The Difference Between 2-Stroke and 4-Stroke Engine Oil

Engine oil is the lifeblood of any motor, providing lubrication, cooling, and protection against wear and contamination. The type of engine in your vehicle, equipment, or recreational toy determines which oil formulation will keep it running smoothly.

Two-stroke and four-stroke engines operate on different principles. Understanding the difference between 2-stroke and 4-stroke engine oil can prevent engine damage, improve performance, and extend the life of your equipment. Whatever type of equipment you’re running, you must choose the right oil.

What Vehicles Use 2-Stroke vs. 4-Stroke Engines?

Before diving into oil differences, it’s helpful to understand which engines you’re likely to encounter in your daily life.

2-stroke engines exist in the following machinery:

Chainsaws and leaf blowers

Outboard boat motors

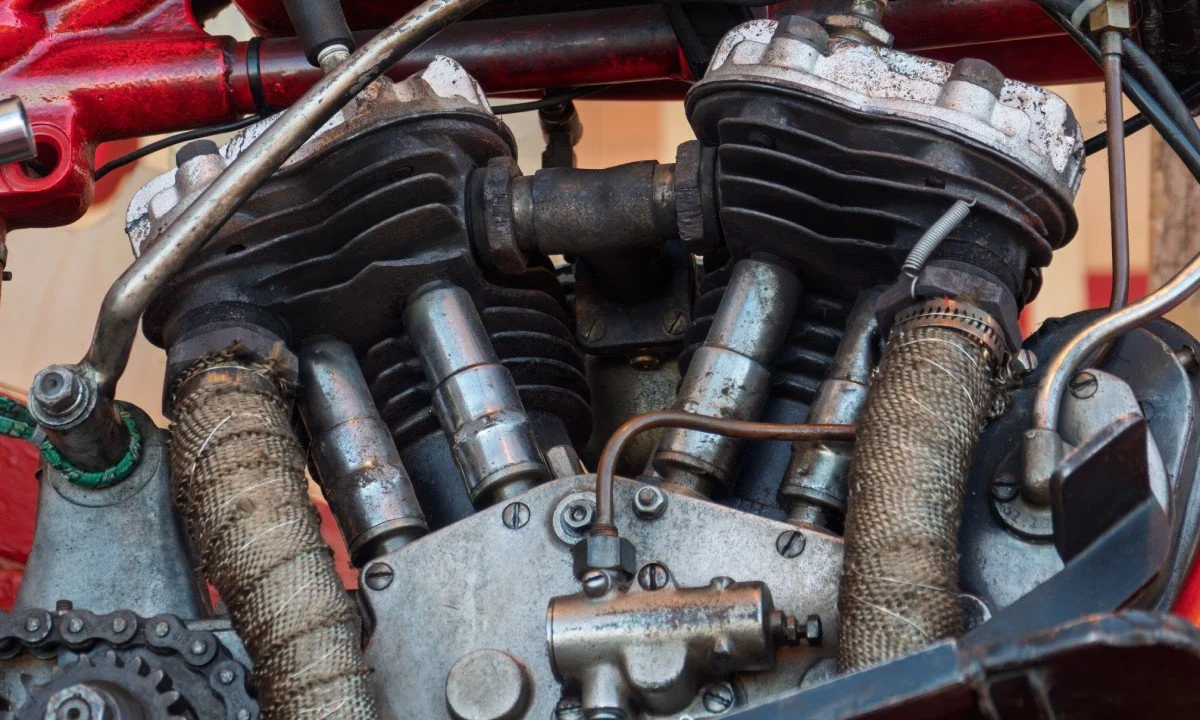

Dirt bikes and some motorcycles

Snowmobiles

String trimmers and brush cutters

Small generators

4-stroke engines power most of the following:

Cars and trucks

Lawn mowers and riding mowers

Most motorcycles

ATVs and UTVs

Inboard boat engines

Go-karts and larger recreational vehicles

Check the engine’s maintenance manual to ensure you’re using the right type of oil.

Difference 1: Lubrication Method

The fundamental difference lies in how oil reaches engine components. Four-stroke engines use a separate lubrication system with an oil pump that circulates oil throughout the engine. This oil remains separate from the fuel and combustion process.

Two-stroke engines take a completely different approach. The oil must be mixed directly with gasoline, either by pre-mixing in the fuel tank or through an automatic injection system. This oil-fuel mixture lubricates engine parts as it travels through the combustion chamber.

Difference 2: Oil Consumption

Four-stroke engines minimize oil consumption. Under normal operating conditions, these engines should use very little oil between changes. Excessive oil consumption in a 4-stroke engine typically indicates worn rings, seals, or other internal problems.

Two-stroke engines consume all the oil you add. Since the oil burns along with the fuel during combustion, you must continuously replenish it. This high consumption rate is considered normal in 2-stroke operation.

Difference 3: Oil Composition and Additives

The additive packages in these oils differ due to their distinct operating environments. Two-stroke oils contain detergent-dispersant additives that keep combustion chambers clean while burning completely. They also include anti-wear agents that must function in the brief moments before combustion occurs.

Four-stroke oils feature more comprehensive additive packages, including viscosity index improvers, anti-foam agents, and corrosion inhibitors. Since these oils don’t burn during normal operation, they can contain additives that would create harmful deposits in a 2-stroke engine.

Difference 4: Oil Location During Operation

In 4-stroke engines, oil remains in the crankcase and oil galleries, separate from the combustion process. This allows for sophisticated filtration systems and controlled oil temperatures.

Two-stroke oil travels a much different path. It mixes with fuel in the combustion chamber, lubricates the piston and cylinder walls, then burns away with each power stroke. This demanding journey requires oils with specific thermal stability and clean-burning characteristics.

Difference 5: Exhaust Smoke Production

Four-stroke engines in good shape produce minimal visible exhaust smoke under normal operating conditions. Thick smoke usually indicates internal engine problems or incorrect oil viscosity.

Two-stroke engines naturally produce more visible exhaust smoke because the oil burns along with the fuel. However, high-quality 2-stroke oils should burn cleanly, minimizing smoke production while providing adequate lubrication.

Difference 6: Environmental Impact

The environmental considerations differ between these oil types. Four-stroke oils remain contained within the engine system during normal operation and can be recycled when changed.

Two-stroke oils burn completely during operation, releasing combustion byproducts into the atmosphere. This has led to strict regulations on 2-stroke oil formulations, especially for marine applications where oil residue can degrade water quality.

Difference 7: Engine Design Compatibility

Engine manufacturers design their products around specific lubrication methods. Four-stroke engines include dedicated oil pumps, filters, and circulation systems that depend on oil viscosity and flow characteristics.

Two-stroke engines rely on the oil’s ability to mix completely with gasoline and provide instant lubrication upon contact with metal surfaces. Using 4-stroke oil in a 2-stroke engine can cause poor fuel mixing, inadequate lubrication, and excessive carbon buildup.

Difference 8: Maintenance Requirements

Maintenance schedules reflect the different demands placed on these oil types. Four-stroke engines typically require oil changes every 3,000–10,000 miles or 25–100 hours of operation, depending on the application and oil quality.

Two-stroke engines require continuous oil replenishment since the oil burns with each combustion cycle. However, they eliminate the need for oil changes since no oil remains in the engine to degrade over time.

Difference 9: Performance Effects

The choice of oil directly impacts engine performance in both systems. High-quality 4-stroke oils maintain viscosity across temperature ranges, supporting lubrication and power delivery throughout the oil’s service life.

Two-stroke oil quality affects combustion efficiency, power output, and engine cleanliness. Poor-quality 2-stroke oils can cause power loss, fouled spark plugs, and excessive carbon deposits.

Difference 10: Cost Considerations

The cost structure is different between these oil types. Four-stroke oils typically cost less per quart but require larger quantities for oil changes. The longer drain intervals can make them more economical over time.

Two-stroke oils often cost more per unit volume but are used in smaller quantities per application. Since you use them continuously rather than in large changes, the immediate cost impact may seem lower despite higher long-term consumption.

Why Choose AMSOIL for Both 2-Stroke and 4-Stroke Engines?

AMSOIL has spent decades developing premium synthetic lubricants for the unique demands of 2-stroke and 4-stroke engines. Their 2-stroke oils feature advanced synthetic base stocks that burn exceptionally clean while providing superior protection in high-temperature, high-RPM conditions.

For 4-stroke applications, AMSOIL’s extended-drain synthetic motor oils offer superior protection and performance compared to conventional oils, often allowing longer drain intervals that can offset their higher initial cost. AMSOIL’s commitment to quality will give you confidence in your equipment’s protection regardless of engine type.

Making the Right Choice for Your Engine

Understanding the differences between 2-stroke and 4-stroke engine oil empowers you to make informed maintenance decisions that protect your investment and optimize performance.

Proper oil selection is just one aspect of good engine maintenance. If you’re looking for a reliable retailer for your oil needs, 1972oil offers the latest AMSOIL products. We have 4-stroke and 2-stroke engine oil available for your needs. Regular service intervals, quality filters, and attention to operating conditions all contribute to long, reliable engine life.